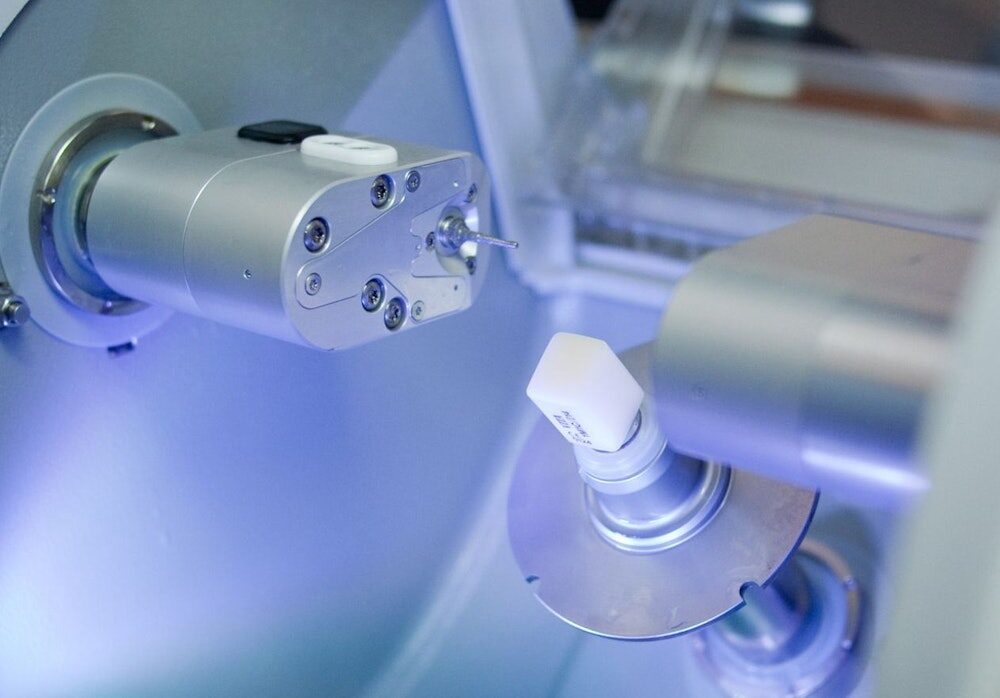

Wet Milling vs. Dry Milling: Which Is Best for Your Dental Lab?

What Is Wet Milling?

Wet milling involves the use of a coolant or water during the milling process. The liquid cools the tools and materials, reduces friction, and washes away excess debris, ensuring smooth and precise cutting.

Advantages of Wet Milling:

- Ideal for Glass-Ceramics and Zirconia Pre-Sintering

- Materials like lithium disilicate or zirconia in its green state require wet milling to prevent micro-cracks and achieve precise shaping.

- Improved Tool Longevity

- The coolant reduces heat, extending the life of cutting tools and reducing wear.

- Smooth Surface Finish

- Wet milling produces a smoother surface, ideal for restorations that require superior aesthetics and minimal polishing.

Limitations of Wet Milling:

- Requires longer cleanup and maintenance due to the use of liquid.

- Machines tend to be bulkier and require coolant management systems.

What Is Dry Milling?

Dry milling uses no liquid coolant, relying instead on high-speed tools and airflow to remove material during the milling process. It is ideal for materials that are harder and do not generate excessive heat during machining.

Advantages of Dry Milling:

- Ideal for Fully Sintered Zirconia and PMMA

- Dry milling is perfect for milling materials like fully sintered zirconia, wax, and PMMA, commonly used for temporary crowns and diagnostic models.

- Faster Workflow

- No need for drying time or coolant cleanup, leading to quicker turnaround times.

- Lower Maintenance Costs

- Dry milling machines are easier to maintain without the need for coolant or liquid management systems.

Limitations of Dry Milling:

- Not suitable for glass-ceramics or pre-sintered zirconia due to the risk of cracking.

- May produce a rougher surface finish compared to wet milling, requiring additional polishing.

Wet vs. Dry Milling: A Side-by-Side Comparison

| Criteria | Wet Milling | Dry Milling |

|---|---|---|

| Best Materials | Glass-ceramics, pre-sintered zirconia | Fully sintered zirconia, PMMA, wax |

| Surface Finish | Smoother, ideal for aesthetics | Rougher, may need polishing |

| Tool Longevity | Extended due to coolant | Moderate, more wear over time |

| Workflow Speed | Slightly slower (requires drying/cleaning) | Faster turnaround |

| Maintenance | More involved (coolant systems) | Easier, lower maintenance costs |

| Initial Cost | Higher due to additional components | Lower, more affordable upfront |

Choosing Between Wet and Dry Milling for Your Lab

The decision between wet and dry milling depends on the materials you work with, your workflow requirements, and the types of restorations you produce:

Choose Wet Milling If:

- You work with glass-ceramics (e.g., lithium disilicate) or pre-sintered zirconia.

- A smooth, high-quality surface finish is critical for your restorations.

- You want to extend the lifespan of your milling tools.

Choose Dry Milling If:

- You primarily work with sintered zirconia, PMMA, wax, or other dry-friendly materials.

- You need faster workflows and lower maintenance requirements.

- Cost-efficiency is a top priority for your lab.

Can You Have Both? Hybrid Milling Machines

For dental labs aiming for maximum versatility, hybrid milling machines that support both wet and dry processes are an excellent investment. These machines allow you to switch between wet and dry milling, giving you the flexibility to handle a wide range of materials without compromise.

Conclusion

Both wet milling and dry milling play a critical role in dental lab workflows, depending on the materials and restorations you’re producing. By understanding their unique advantages, you can choose the method—or invest in a hybrid machine—that best fits your lab’s needs.

Explore our online store to discover high-quality dental milling machines, tools, and accessories to take your lab’s efficiency and precision to the next level!